Page 115 - PROTAGONIST-120

P. 115

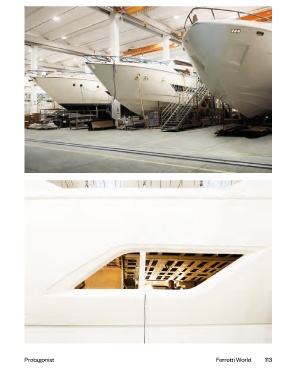

Page 111: Milling machine in the molds division Page 113: Above, Cattolica shipyard interiors

Below, a Ferretti Yachts hull

During our exploration, we realize that in the shipyard one can sense the

essence of know-how in the shaping of material; we are surrounded by

imposing opaque forms that will give rise to incredible hulls made of light

and brightness.

The story begins precisely in Forlì: more than a production customization of interiors for individual clients.

plant, this is a veritable chapter of the history of shipbuilding. Each of the two shipyards has its own particular character-

An area of 14,000 square meters for a paragon of productive istics. Arriving at the facility in Cattolica, we are enveloped in a

excellence on a European scale. The shipyard is a production contemporary world; the production center has been in operation

facility for the boats of the Ferretti Yachts brand. One outstand - since 2001 and contains as many as sixteen assembly stations. A

ing feature is the zone set aside for the creation and manufac - facility that complies with the most modern criteria of efficiency –

ture of the molds and models, a unique specimen in terms of just consider the fact that it is possible to simultaneously build 16

size as well as its remarkable level of technology and automa - motor yachts inside it, ranging from 20 to 30 meters in length. The

tion. The production process of the shipyard relies in fact on shipyard features an “island” production system, a case of excel-

highly advanced methods based on digital systems of control of lence that allows every workstation to be absolutely independent.

temperature and humidity, climate cells for thermoregulation This means that once completed each boat can be moved without

of resins and systems of traceability and control of materials interfering with the work of the other stations, thanks to a con-

through laboratory analysis. In particular, the molds division is venient frontal route of exit. The construction site in Cattolica

equipped with a numerically controlled milling machine with a also has a splendid private dock for testing and trials in the water.

length of 30 meters, one of the largest in Europe. Cattolica, Forlì, timeless cities that are icons of an utterly

Continuing our exploration, we realize that in the shipyard Italian style made of history, architecture, and the sea. Having

one can sense the essence of know-how in the shaping of ma - the privilege of visiting the Ferretti Yachts shipyards means being

terial; we are surrounded by imposing opaque forms that will surprised by the fact that these places are also much more: auto-

give rise to incredible hulls made of light and brightness. We mation, analysis of materials, advanced, production systems. In

can truly discover the showroom, however, in the architectural a word: future. Cattolica, Forlì, two shipyards where immaterial

structures themselves, an antithetical world made of precious knowledge meets high technology, examples of excellence of in-

finishes and refined fabrics that reveal the most personal, in - dustrial design that are also striking due to their spontaneously

ternal part of the shipyard, involving the infinite possibilities of film-like atmosphere.

112 Ferretti World Protagonist Protagonist Ferretti World 113